Since our establishment in 1898, “creating bamboo crafts to enrich lives” has been our corporate philosophy. While protecting tradition, our theme is “to combine the classic and the modern” and to propose new styles of bamboo craft.

Working with “bamboo” as a raw material for generations, we have developed a wide variety of original products, from artistic handicrafts to daily items, with a unique sensitivity that derives from our founder, a painter in Edo era. All our products are manufactured at an exclusive studio affiliated with our studio for decades.

Today, we have a line-up of more than 1000 items.

Our main business is wholesale, and we have approximately 500 retail partners including famous department stores, interior goods shops, and luxury traditional inns (ryokan) all over Japan.

Focusing our efforts on retail in recent years, we opened our first flagship shop in Kyoto in October 2011 in order to bring the beauty of bamboo handicrafts to our customers.

Not content with tradition alone, we create products that complement contemporary lifestyles using techniques cultivated up to now.

Using bamboo in earnest as a raw material, our products are carefully made with great care, right down to each detail, making use of the material.

We seek to make “beauty” in functional products such as everyday items.

Bamboo has been incorporated in our daily lives in many ways, used to make items such as chopsticks and baskets.

Bamboo crafts such as flower baskets and tea ceremony utensils like tea whisks and tea spoons are essential in the three major performing arts in Japan: sado (tea ceremony), kado (flower arrangement), and kodo (traditional incense ceremony).

Bamboo has played an important role in Japanese daily life and culture.

Furthermore, bamboo matures in four to five years and does not need agricultural pesticides, making it environmentally-friendly.

Bamboo can also be used as a substitute for wood, making it a sustainable material for future generations.

We continue to make bamboo products that function as everday items appropriate for 21st century lifestyles.

The bamboo that we use is harvested between the cold winter months of November to February.

And when it gets warmer in March, the oil from the bamboo is removed through steaming in a special kiln. Thereafter, it is hung to dry in the sun for over one month.

(This period is limited in order to avoid the rainy season.)

Japanese timber bamboo is mainly used for weaved crafts like baskets, while moso bamboo is used in cut and carved crafts such as chopsticks.

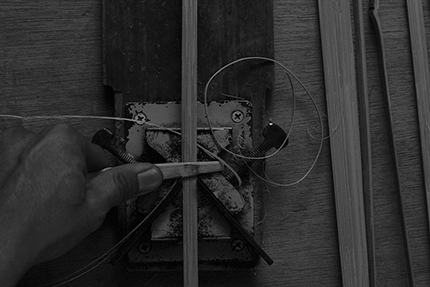

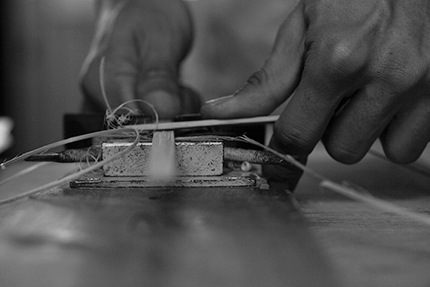

The bamboo is first roughly cut using kiku-wari, a knife created only for chopping bamboo.

If the bamboo is finished with dyeing or lacquering, the surface is shaved in a fixed direction using a short blade.

(This might be done using a machine, depending on item.)

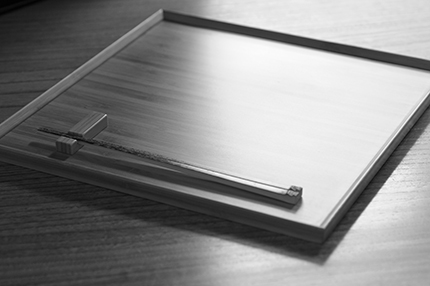

The bamboo width can be adjusted by using a tool that can cut to the right millimeter.

Depending on the product it’s used for, the bamboo can be cut into thickness of 0.2-0.5mm using special tools.

Most of the items are finished with dyeing. Bamboo is dyed two to three times, before and after weaving, while some items are finished by lacquering. Lacquering is applied twice, and it takes four to five days to dry.

Weaving work is done almost 100% by hand. Only the delicate and expert technique of artisans can make this possible.

A process called “carbonization” is carried out by steaming in a high pressure kiln to prevent warping and to repel insects.

Tools such as belt sanders or routers are used but the thickness or curves of the bamboo are hand-carved by artisans.

Since culinary tools such as chopsticks and cutlery are our main products, they are coated with urethane in order to give more durability. Depending on the product, some items are lacquered or not coated at all.